Dive Brief:

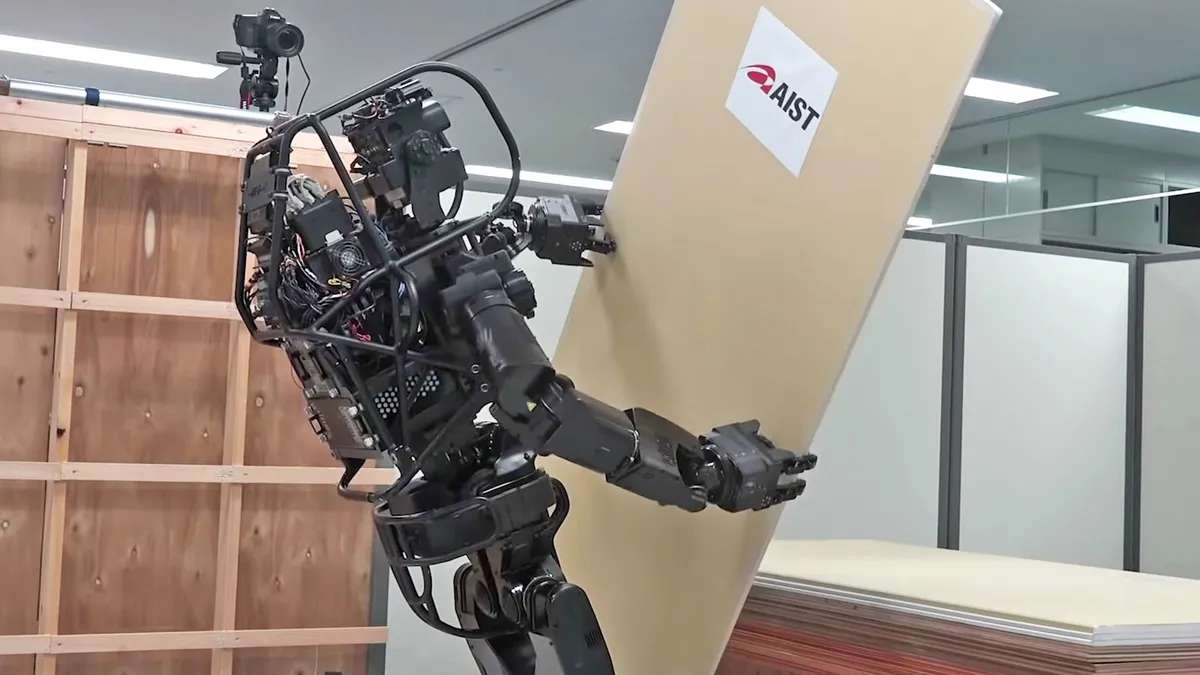

- Researchers at Japan’s Advanced Industrial Science and Technology Institute have built HRP-5P, a humanoid bot prototype, reported Engadget.

- The bot combines environmental detection, object recognition and careful movement planning to install drywall independently, including hoisting boards and fastening them with screwdrivers. To make up for its lack of movement compared to a human, HRP-5P has numerous joints that flex to degrees people are unable to. It also can correct for slips and is capable of fields of view beyond that of a human worker's.

- The team hopes to collaborate with private companies that will treat the bot as a development platform and lead to further breakthroughs. The robot is meant to tackle the “manual shortages” Japan is facing, AIST also posits, and will allow the limited pool of human workers to focus on lighter, less dangerous work.

Dive Insight:

AIST is just one company in Japan looking to robots to help solve the country’s labor shortage. Between an aging population and decreasing birth rates, Japan expects its construction labor pool to fall to 2.2 million by 2025, compared to 3.4 million in 2014. Earlier this year, Shimizu Corp. announced it was in the final stages of developing autonomous robots it hopes to deploy on a high-rise construction site in Osaka. Those robots are intended to carry material, work on floors and ceilings, and weld steel columns.

Domestically, Purdue University’s Polytechnic Institute is working with automation software and robotics to improve and advance the construction process. Assistant professor Jiansong Zhang is focusing on algorithms that can support future automation on the jobsite so that robotics technology can continue the machine learning process.

Autodesk also is hoping to advance construction robotics through its BrickBot, a robot that uses artificial intelligence to autonomously complete complex assembly tasks. It’s still in the testing stage and is erecting Lego structures, but researchers hope it can be scaled up to eventually be used for factory and construction applications.

Already impacting construction processes are the rebar-tying Tybot, the brick-laying semi-automated mason and various robotic devices aimed at supplementing human labor.

The industry is ripe for opportunity in automation. A January report from the Midwest Economic Policy Institute estimated 49% of all construction jobs could be automated, which could displace or replace up to 2.7 million construction workers by 2057. Although that automation could help with the labor shortage, as well as with increasing the industry’s productivity, it still has the potential to put many out of work. As such, the report’s authors made several recommendations, including re-skilling the workforce to work in tandem with automation.