WSP thinks the construction industry of the future will use a lot more 3D printed concrete, and the Montreal-based contractor is researching new applications for it, including infrastructure and clean energy projects. The method can help reduce labor cost, waste and planning time, according to a study published in the scientific journal MDPI.

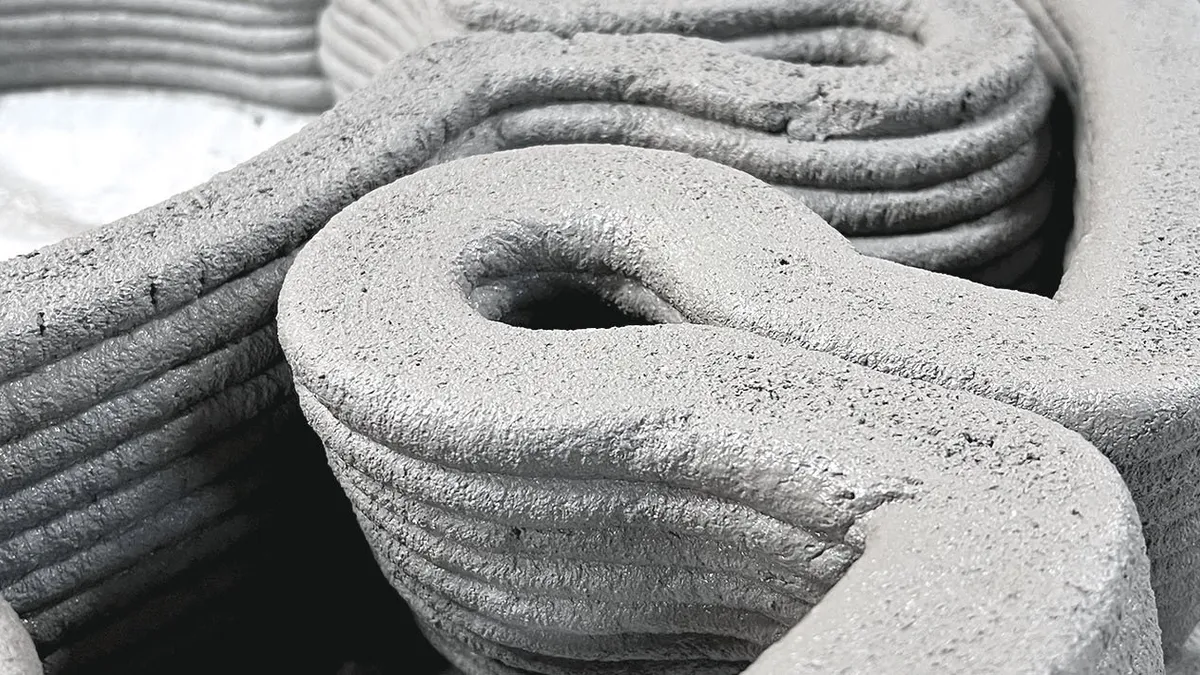

With 3D-printed concrete, a robot layers beads of concrete to build structures from the ground up and can print odd shapes without formwork, making it ideal for vertical construction. In partnership with Boulder, Colorado-based renewable energy company RCAM Technologies, WSP is developing unique ways for clients to use the method.

Among the new applications WSP and RCAM are working on clean energy components, such as wind turbine towers and land-based wind turbine foundations, support structures for offshore wind turbines, anchors for floating offshore wind turbines, deep-sea pumped hydroelectric storage units and floating offshore solar energy structures.

3D-printed concrete has been used to create homes, military barracks, office buildings and even a bridge. There’s been exponential growth in the method’s use and development, and that looks set to continue, Markus Wernli, who specializes in structure design and is vice president of the maritime division at WSP in the U.S., said in the release.

“The technology is impacting the housing sector and its reach is expected to eventually expand into heavy infrastructure,” said Wernli. “The use of 3DPC will first grow in less challenged structural and non-structural components before finding application in components for large infrastructure.”

Rather than replacing traditional cast-in-place and precast concrete, 3D printed concrete will likely complement them and “become another tool in the toolbox for the construction industry,” Wernli said.

Aspects for further development include new robotic construction methodologies, according to WSP, and there’s also potential to expand to more sustainable materials, such as geopolymers.

“Environmental stewardship is another important aspect that needs to be considered for the future success of 3DPC,” Wernli said. “This includes the development of low-carbon and [low-] energy footprint materials. Other, non-cementitious materials are already in development such as polymer concrete and wood composites.”

Challenges persist

While 3D-printed concrete has many unique strengths and is suitable for vertical construction, it’s challenging to use for horizontal structures because they require a massive printer. The larger the build area, the more complicated it is to design and construct a 3D printer.

Plus, there’s not yet an ideal solution for the printing process to reinforce concrete components because the material behaves differently when loaded in one direction or in another direction, according to WSP.

In addition, many jurisdictions don’t yet cover 3D printing materials in their building codes, and gaining the necessary approvals can be a lengthy and expensive process, according to Patti Harburg-Petrich, principal in the Los Angeles office of U.K.-based engineering firm Buro Happold. It takes a very long time for new technologies and building innovations to get incorporated into codes.

Nonetheless, the technology is gaining momentum, and the automation of this aspect of building will shift needed labor skills from traditional construction to printing operators and maintenance workers, according to WSP. Additional workers will also be needed for planning and programming, printer setup and development of future types of printers and materials.