The home of college football's historic Citrus Bowl is getting a massive makeover.

Barton Malow's Florida team is completing updates to enhance the fan experience, entertainment value and overall aesthetics of the 85-year-old Camping World Stadium in Orlando, Florida. Stadium owners and city officials hope that the upgrades will help attract even more marquee events.

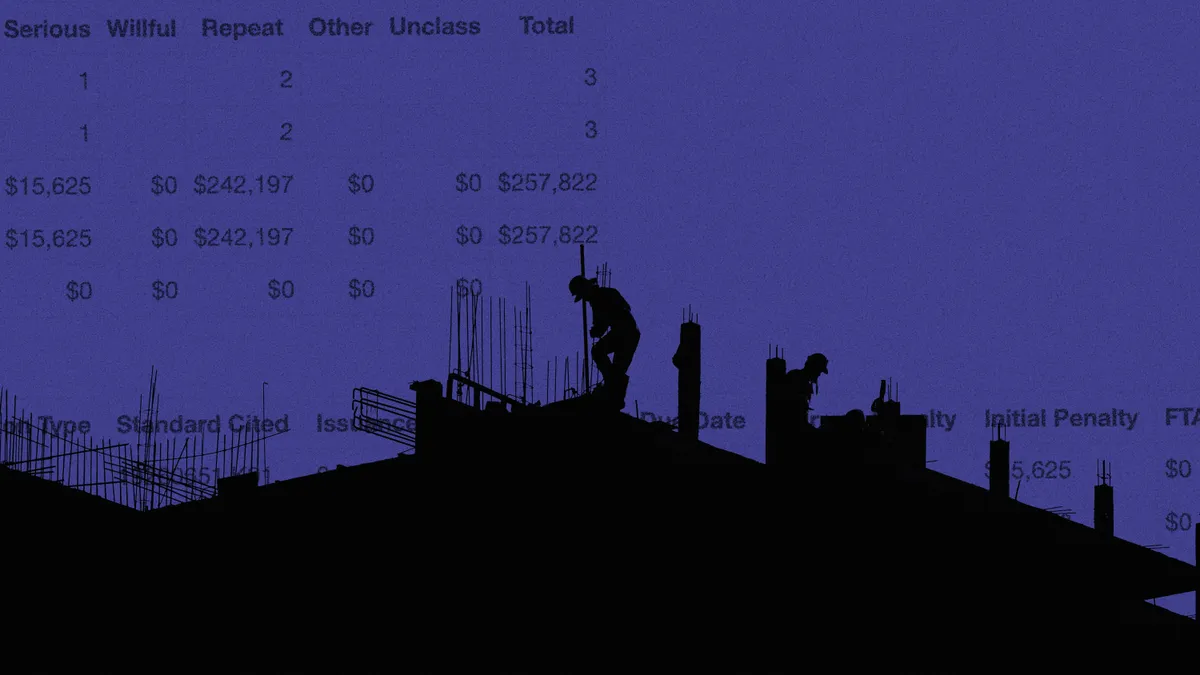

But performing a large-scale $47 million renovation within the complex confines of the existing stadium structure presented some unique challenges. One of those challenges was the demolition of the existing precast seating units that were being replaced with new mezzanine club structures (shown above in rendering).

Here, Construction Dive talks with Barton Malow Project Manager Logan Crutchfield, about the special techniques used to remove the seating units while events continued at the venue.

CONSTRUCTION DIVE: Tell us about how you removed the seating units.

LOGAN CRUTCHFIELD: In order to accomplish the demo, the team had to hoist and rig the precast seating unit assemblies up and over the existing terrace level of the stadium in order to remove them. They used a 300-foot-tall luffing jib crane with a customized, cantilevered, double spreader bar to balance the weight during removal. The weight of the assembly was about three times the weight of the precast seating unit itself. The detailed plan that we put together for the demolition of the existing mezzanine area was truly a unique challenge and a collaborative learning experience for our team. We tapped into the minds of various other subject matter experts throughout Barton Malow for input and to review our final plan before executing it.

What were some other challenges of the project?

Another significant challenge is the ongoing operations taking place at Camping World Stadium throughout construction. With crowds of up to 10,000 people, safety is our No. 1 priority along with maintaining an appropriate work environment, proper access and egress for all occupants and easy public access. In order to keep people safe and away from construction zones, we've had to install about 1,600 feet of event-ready engineered partitions. We accounted for two Supercross events and a Monster Truck Jam event within the first six weeks of construction.

What type of technology was used to help with these challenges?

A point cloud survey was performed by Barton Malow's team. This was beneficial in overlaying and reviewing existing condition information with a design team that spanned several states.

How have you been able to keep workers on the project safe and healthy during the COVID-19 pandemic?

Fortunately, the construction on this project takes place primarily outdoors throughout the majority of its duration. However, we closely abide by guidelines that our risk management team has instituted. This includes daily QR code-based screening before workers are permitted to enter the jobsite, 100% mask wearing at all times and increased cleaning and disinfecting of commonly touched or accessed spaces.

What is the next step for the renovation?

The next significant step is placing steel in the area where we demolished the precast units. The steel will serve as the structure for the stadium's new suites. Complex steel erection methods include using mini crawler spider cranes and tugger hoists to complete this work.

Aside from the new mezzanine suites, we're adding 3,000 seats to the north end zone, about 6,000 square feet worth of bathrooms and concessions space and re-designing the main entryways. We'll likely be on site for all of 2021 as we turn Camping World Stadium into a more modern facility designed to enhance the fan and athlete experience.

How was this project different from other stadium projects you've worked on?

What's interesting about Camping World Stadium is that it doesn't serve as the "home venue" to any particular team. It hosts a number of different sporting and entertainment events including the Monster Truck Jam, NFL Pro Bowl, Citrus Bowl and many other games, outdoor concerts, and activities throughout the year.

Additionally, the need to integrate with the local community is more important than ever on this project. Barton Malow in partnership with other team members Collage, JCB Construction, C2 Advisors and Provisions have been working closely with the city to provide subcontractor outreach events and matchmaking sessions to allow for maximized local, diverse and small business opportunities on the project.